About Us

The industrial business you can feel.

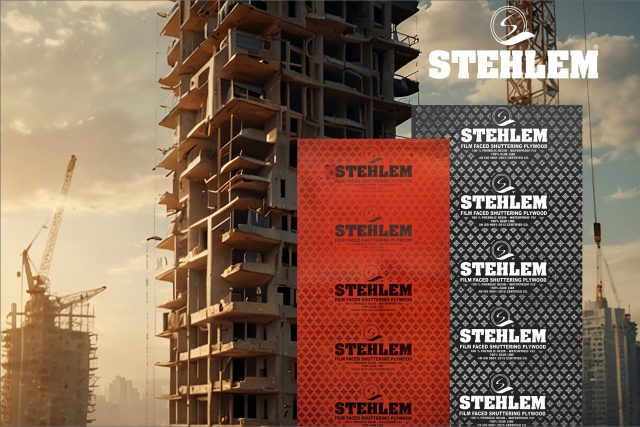

We Jagramji Plywoods Pvt. Limited is a top rated manufacturer of Wood composites in India. Our state of art factory is situated in the core zone of Indian plywood industries i.e. Yamuna Nagar, Haryana.

Why Choose Us

For builders, contractors, and industrial specialists, Jagram Ji Plywood stands out as a reliable partner when it comes to plywood and wood solutions. The following justifies picking us for all of your plywood and wood requirements:

- Uncompromising Quality

- Innovation and Expertise

- Reliability You Can Trust

- Uncompromising Quality

- Innovation and Expertise

- Reliability You Can Trust

Our Stats

A key component of construction is shutter plywood, which is used to make moulds for concrete constructions. Its strength is essential; premium plywood has the ability to support weight. It is usually composed of hardwood and has an 8–12 reuse limit, which makes it affordable and long-lasting for big projects.

Ask by Client

Frequently Asked Questions

1. What is shuttering plywood? Shuttering plywood is used as a formwork material to create molds for concrete structures. It is known for its durability and ability to withstand the pressures of wet concrete.

2. What are the key features of good shuttering plywood? High-quality shuttering plywood should be moisture-resistant, strong, and capable of withstanding repeated use without warping or delaminating.

3. Can shuttering plywood be reused? Yes, good quality shuttering plywood can be reused multiple times depending on its condition and the care taken during handling and storage.

4. How should shuttering plywood be stored? It should be stored in a dry, covered area to protect it from moisture and direct sunlight, which can cause damage.

1. What is chequered plywood? Chequered plywood features a patterned surface with raised or embossed patterns, often used for flooring or in areas requiring extra grip.

2. What are the benefits of using chequered plywood? It provides excellent slip resistance, durability, and is aesthetically pleasing, making it ideal for industrial flooring and high-traffic areas.

3. Can chequered plywood be used outdoors? Yes, but ensure it is treated or coated for weather resistance if exposed to outdoor conditions.

4. How do you clean chequered plywood? It can be cleaned with mild detergent and water. Avoid harsh chemicals that could damage the surface finish.

1. What is a composite hardware pallet? A composite hardware pallet is made from a blend of materials such as wood fibers and plastics, offering durability and resistance to environmental factors.

2. What are the advantages of composite pallets over wooden pallets? Composite pallets are more resistant to moisture, pests, and chemicals, and they generally have a longer lifespan and are easier to maintain.

3. Are composite pallets recyclable? Yes, composite pallets can be recycled, but the process may vary depending on the materials used in their construction.

4. How much weight can composite pallets handle? The weight capacity depends on the design and materials of the pallet, but they are generally designed to handle heavy loads efficiently.

1. What is fire retardant plywood? Fire retardant plywood is treated with chemicals to enhance its resistance to fire, slowing the spread of flames and improving safety in construction.

2. Where should fire retardant plywood be used? It is ideal for use in areas where fire resistance is critical, such as commercial buildings, public spaces, and high-risk environments.

3. How long does fire retardant plywood last? Its effectiveness can last for several years, but it’s important to follow manufacturer recommendations for maintenance and reapplication of fire retardant treatments if necessary.

4. Can fire retardant plywood be painted or stained? Yes, but ensure that the paint or stain used does not compromise the fire retardant properties of the plywood.

1. What is the difference between H beams and I beams? H beams have a wider flange and web compared to I beams, offering greater stability and strength for structural applications. I beams are typically used where high strength-to-weight ratios are needed.

2. What are the common uses of H beams? H beams are commonly used in heavy structural applications such as in the construction of bridges, buildings, and industrial structures due to their strength and durability.

3. What are the advantages of I beams? I beams are designed to handle bending forces efficiently and are often used in lighter load applications such as residential construction and support structures.

4. How do I choose between H beams and I beams? The choice depends on the specific requirements of the project, including load-bearing capacity, span, and design considerations. Consult with a structural engineer for the best option.

Testimonials

Client’s Testimonials

"The quality of their laminated veneer lumber is top-notch. It provided the stability and support we needed. Highly recommend!"

"Jagram Ji Plywood’s scaffold planks are incredibly sturdy and safe. We trust them for every project, big or small."

Join Us

Stay Updated!

Get Updates By Subscribe Our Weekly Newsletter

"Jagram Ji Plywood’s shuttering plywood exceeded our expectations in strength and durability. A reliable partner for all our construction needs!"